"StudyStudyStudy" (jesterjin)

"StudyStudyStudy" (jesterjin)

12/22/2016 at 14:15 • Filed to: None

10

10

0

0

"StudyStudyStudy" (jesterjin)

"StudyStudyStudy" (jesterjin)

12/22/2016 at 14:15 • Filed to: None |  10 10

|  0 0 |

With the engine acquired I started picking up the ancillaries to make things work.

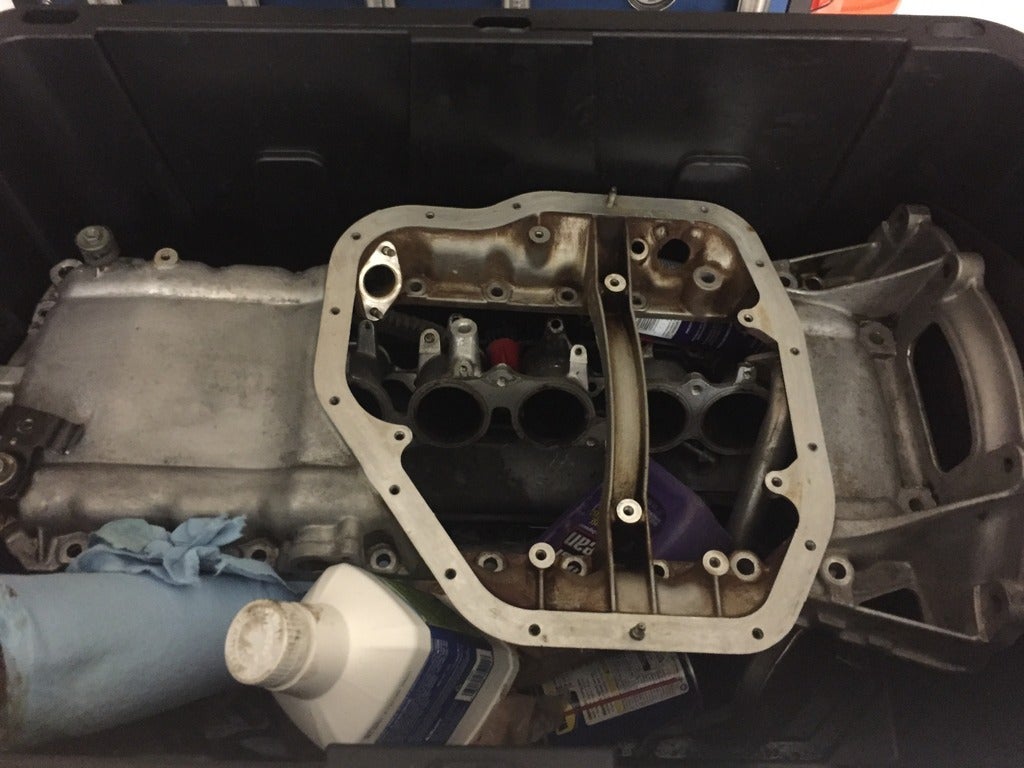

I pulled off the cross over intake, the exhaust manifold and the pan was off for the trade. I decided before I pulled the head I would clean up the block while sealed.

First off was to clean the gunk out of the block and the pan. I swear some people must have had a really really bad experience with gasket maker/form in place gasket/silicone and just go absolutely over kill with the stuff. The 7m had the oil drain almost completely blocked with excess silicone. This engine had a butt load of silicone oozing into the pan.

After cleaning the gunk out and razor blading the mating surface to clean off the bits of silicone, I decided to clean the oil pan. I wanted to stay away from the machine shop originally as my hope was to clean up the motor and regasket the major pieces and just drive it for a while, so I decided to clean the pan at a big wash sink at work. Over three weekends I worked on the pan that you can see in the background of pictures above. Finally I ended up with this.

I have tried a lot of cleaning products over the years, brake clean, soap, oven cleaner, etc etc and even on this pan I tried using three different degreasing products, but the best ended up being mineral spirits. Brushed on or poured on it did little, but sprayed on with a spray bottle and agitating it and repeating worked wonders.

With the pan off and clean I decided to tackle the oil return fitting. Toyota was nice enough to program the casting into all the pans even though it was only used on the turbo variants, thus on most pans (I have seen a few without) have the dimple and even two pilot holes drilled for screws. I measured these pilot holes at 4.3 mm and 15mm depth.

As I wanted something a little more substantial then an M5, I stepped up to an M6 and I drilled down about 10mm more to allow my tap to engage enough threads.

Some people suggested you can do this on the car, but that would be a mistake, the amount of aluminum you have to drill through is substantial and the bits go absolutely everywhere.

With the pan cleaned and prepped next came cleaning the hardware. THis took about three hours of cleaning with a knife and a sponge and soap.

You can see the still dirty bolts in the upper left. My fingers were raw from chasing all the reads, but doing it this way you don’t cut into the coating and expose raw metal. Being a newer motor and not 40 years old everything came out pretty nice with just a simple clean.

Next will be going over all the parts I had to replace on this gone over motor.

Money spent:

Cleaning products and brushes -50

Bolts, washers, drill bits - 30

Subtotal - 80

Total spent - 22644

!!! UNKNOWN CONTENT TYPE !!!

!!! UNKNOWN CONTENT TYPE !!!